Carbon Solutions for Industry & Utilities

Alcon Development supports clients across the full chain—from feedstock preparation and pyrolysis to activation, QA/QC, and application engineering—so carbon products deliver measurable performance in water, air, and soil systems.

Why partner with Alcon Development?

- Design-to-operate advisory with vendor-neutral selection.

- Integration with real-world utilities: emissions, noise, ATEX, and permitting in mind.

- Clear QA/QC plans and certification pathways (EBC/IBI, GAC performance tests).

- Pilot coordination and scale-up support.

What we deliver

Process Design

Vendor-neutral selection of pyrolysis and activation technologies tailored to your feedstock, scale, and regulatory needs.

Plant Integration

Feed handling, gas clean-up, emissions control, ATEX zoning, utilities tie-ins, and commissioning support.

Applications

GAC/PAC systems for drinking water and air; biochar for soil improvement and carbon sequestration.

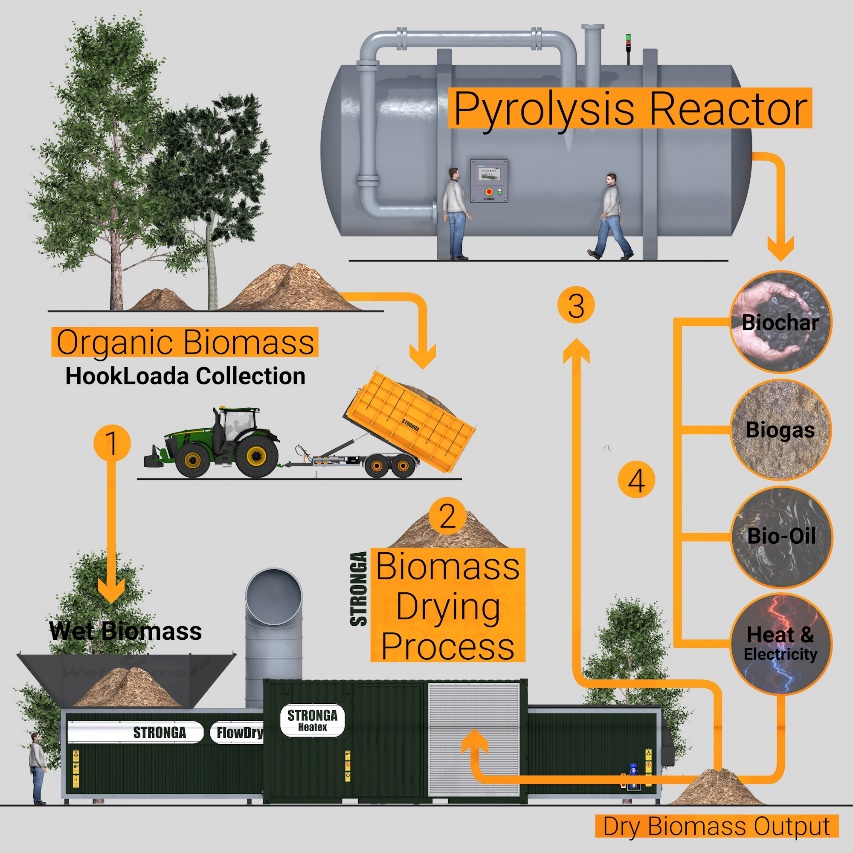

Process overview

How it is made

A compact, scalable pathway from biomass to high-performance carbon products.

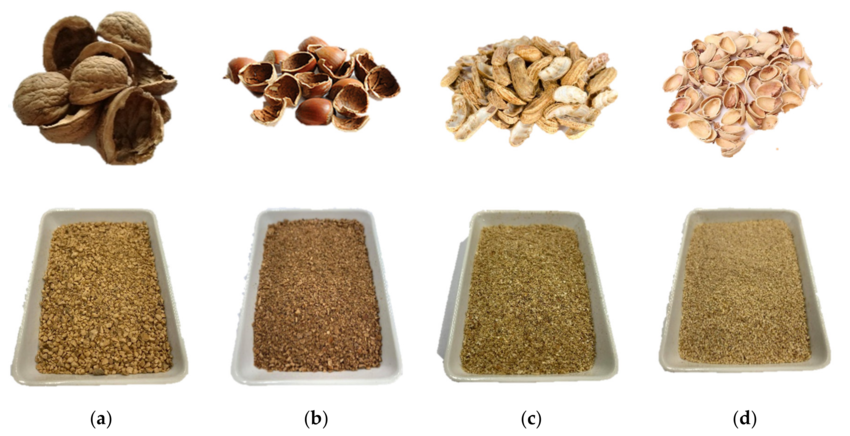

Feedstock Preparation

Cotton stalks, wood residues, or nutshells are dried and sized for consistent conversion.

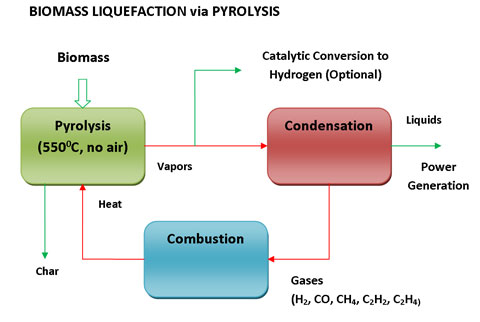

Pyrolysis → Biochar

Oxygen-limited heating at ~400–700 °C produces biochar plus process vapors/gases.

Activation → Activated Carbon

Steam or CO₂ at ~800–1000 °C opens porosity and boosts surface area for adsorption.

QA/QC & Grading

Washing, drying, and grading into GAC/PAC/pellets; iodine number, BET, and performance tests.

Designs align with EBC/IBI biochar guidance and EPA notes for GAC/PAC systems

use cases

Drinking Water

GAC filters remove VOCs and other organics; designed beds are regenerable and auditable.

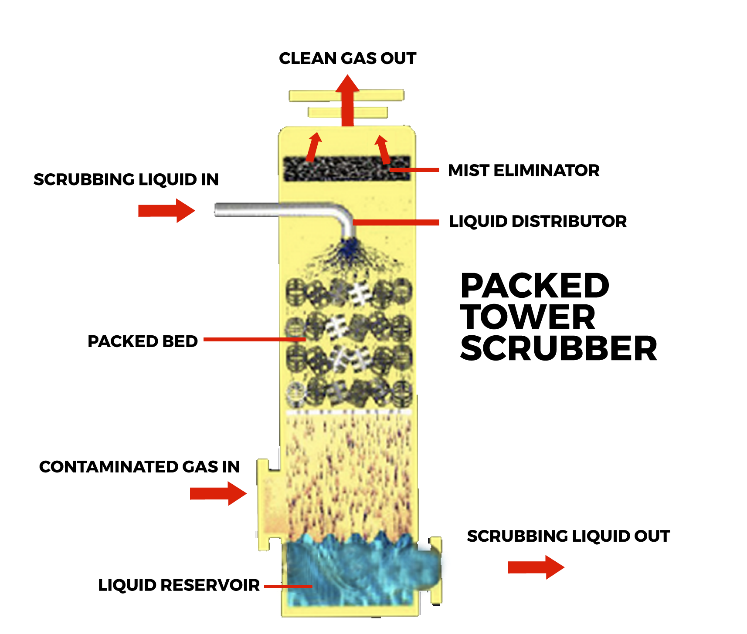

Industrial Air

Capture solvents and odors with packed beds or modular adsorbers integrated into existing lines.

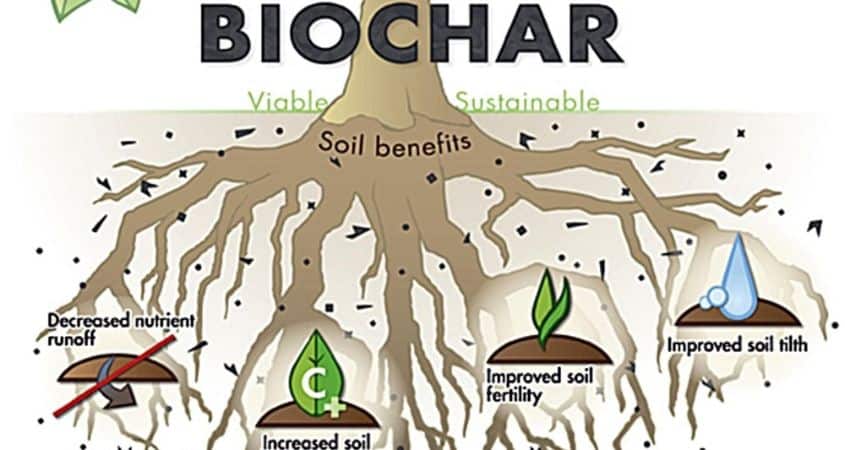

Soil & Carbon Sinks

Biochar improves soils and enables durable carbon storage with traceable accounting.

Standards & Compliance

Standards-aligned by design

We map each project to recognized guidance—EBC and IBI for biochar; EPA technology notes for activated carbon.

impact callout

Up to 99.9% removal for many VOCs with GAC

(design-dependent)

PFAS treatment

GAC is an EPA-listed option when correctly engineered.

Scalable footprints

containerized modules for pilots through full-scale.

FAQ

Biochar targets soil benefits and carbon storage; activated carbon is engineered for adsorption in water and air systems.

Yes—when appropriately designed, GAC is a recognized option for PFAS control alongside IX and RO/NF.

Dried agricultural residues (e.g., cotton stalks), wood residues, and nutshells perform well; selection depends on ash and volatiles.